Aclima Wool Layering System

Uncompromising design for uncompromising wool products

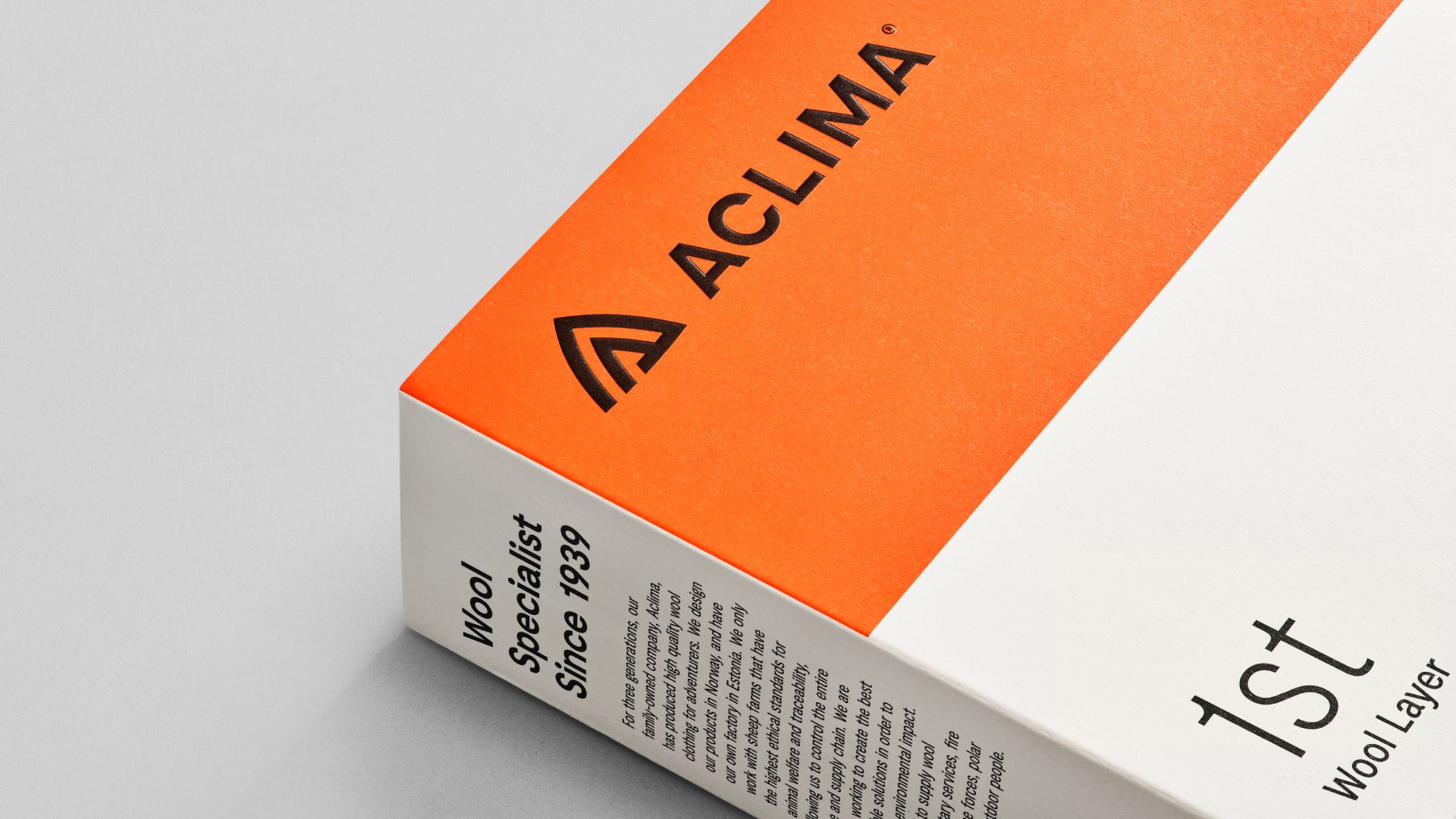

Aclima is a Norwegian textile manufacturer established in 1939. They design and produce functional wool garments adapted to outdoor activities. The company’s long history of supplying the Norwegian military, police forces, polar expeditions, the outdoor market, and by maintaining close dialogue with target groups who demand quality and functionality, has given Aclima unique cutting-edge expertise.

Aclima is committed to making clothes with the highest possible quality that last a long time, produced in as sustainable way as possible. They wanted the same for their new packaging concept. The goal was to "create the best possible packaging solution for their customers - and themselves". They wanted to be clearer, make it easier to navigate and reduce the number of variants.

Aclima is investing internationally and needed to be able to easily explain the flexibility of dressing in several layers, the value of buying the right garments – not many garments, as well as highlighting wool’s unique user benefits. In addition, it was a goal to reduce the number of packaging variants.

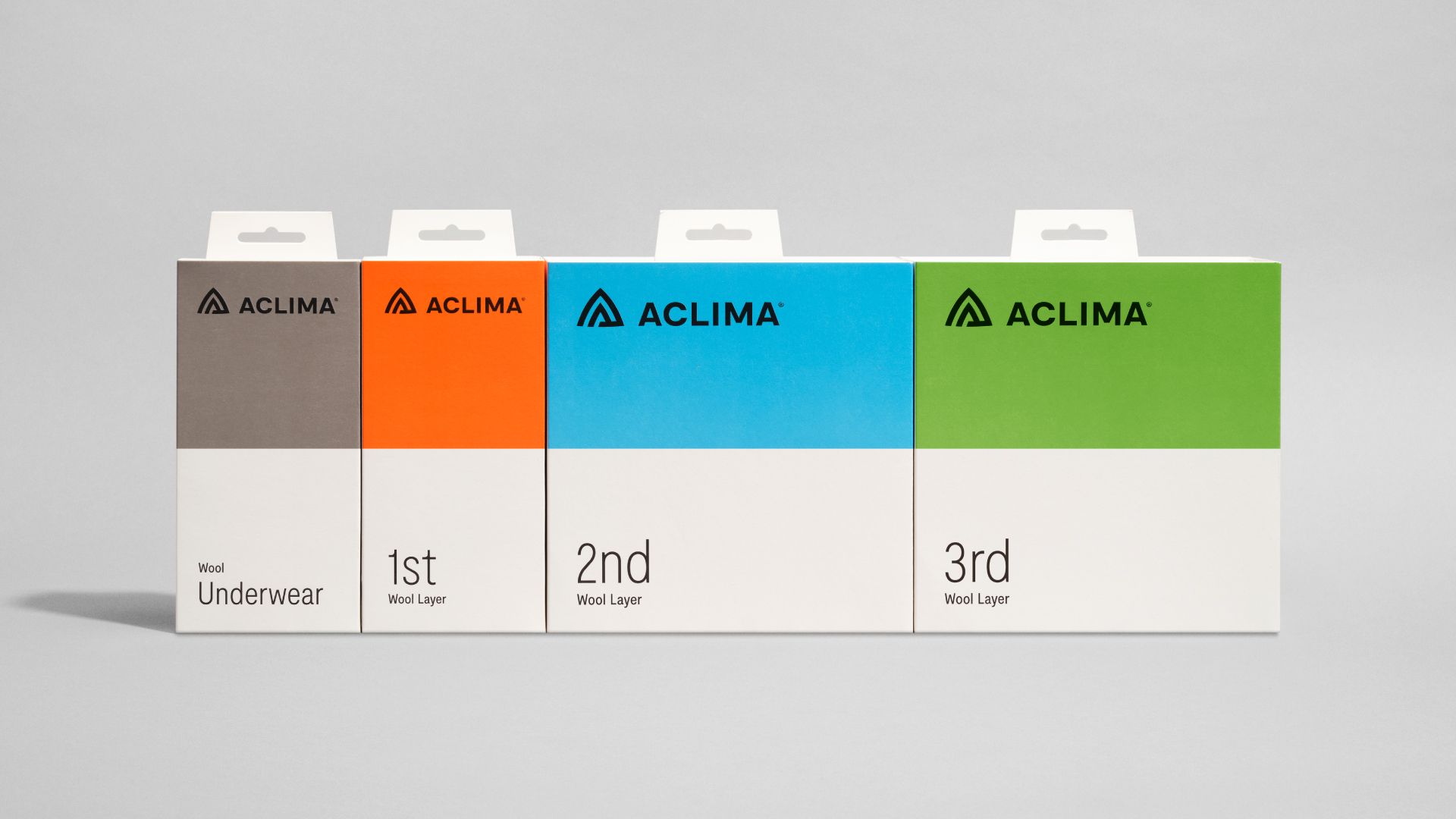

We developed a concept that was both relevant and modern, at the same time as it should be lasting and gave a lot of flexibility. We were inspired by the values Aclima hold dear, quality and functionality, and developed a concept with a direct and essential design language – Aclima Wool Layering System.

The front part of the packaging boxes for layer Underwear (gray), 1st (Orange), 2nd(Blue) and 3rd (Green) was divided horizontally into two parts to create a "layer upon layer" perception together with the front label with all the variable information.

The layering concept was made evident with rigid text hierarchy supported by signal colours that create visibility in the store. Inspired by Aclima’s determination to use renewable material and to reduce environmental impact the packaging die line was redesigned to minimise as little use of glue as possible while keeping the packaging sturdy. The packaging is made of recyclable paper and zero plastic, and by putting variable information on the front labels we were able to reduce the number of packages and create a more flexible solution. A gain in itself – both for the environment and logistically for Aclima.

For Neue, it is always a goal to focus on one clear story. Our approach therefore fit the task perfectly and we were just as uncompromising in stripping away everything unnecessary, as Aclima is uncompromising in its attitude to deliver quality products.

Credits